In the era of industrial automation and efficiency improvement, "precision" has become one of the key indicators to measure product quality and technical level. Today we are going to introduce a revolutionary equipment- electronic dog fixed flow range speed measurement precision radar , which not only represents a new breakthrough in modern science and technology, but also an important helper for enterprises to achieve fine management.

Revealing the core advantages of electronic dog radar

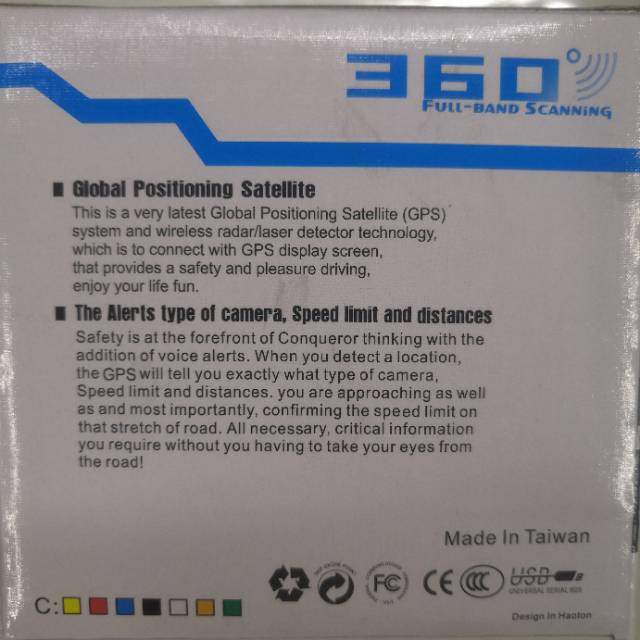

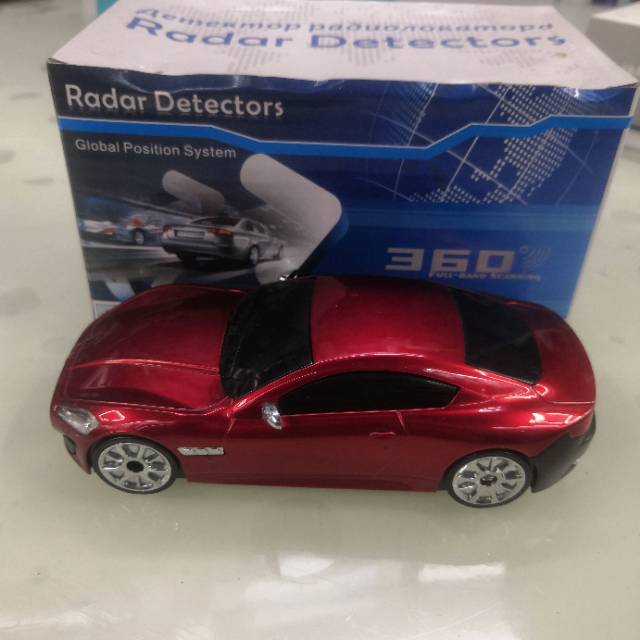

This high-tech product uses advanced sensor technology and signal processing system, which can complete high-precision speed detection tasks in complex environments. Its core components are made of durable and sensitive materials that can withstand harsh conditions for long periods of time without loss of accuracy. In addition, the instrument also has the characteristics of simple operation and rapid response, which is very suitable for various dynamic monitoring scenarios.

Why Precision Measurements Are Essential to Modern Industry

With the increasingly fierce market competition, the requirements for every link in the production process are constantly improving. Only through accurate data collection can we find potential problems in time and take corresponding measures to improve them. For example, in the manufacturing industry, if the actual operating conditions of machinery and equipment cannot be effectively grasped, it may cause a waste of resources or safety hazards; while in the field of transportation, reasonable planning of vehicle routes depends on the support of reliable real-time vehicle speed information.

How does speed monitoring work in a fixed flow range

This electronic dog radar is specially designed for in-depth research and development on the change law of object movement rate in a specific interval. Capture more subtle differences in motion by automatically adjusting the scan frequency with a built-in program. At the same time, the reliability of the calculation results is further improved by combining external input parameters (such as temperature, humidity and other factors). This means that you can get consistent feedback on your results, both on the assembly line and on the construction site.

Practical application scenarios: from manufacturing to logistics

In addition to the traditional industries mentioned above, this technology can also be widely used in many other market segments. For example, in the process of food processing, it is necessary to closely track the rotation times of mixer blades to ensure the uniformity of taste. The express sorting center relies on high-speed cameras and software algorithms to count the position distribution on the parcel conveyor belt, etc. All of this requires a set of proven solutions as a supporting foundation.

How to choose the most suitable speed measurement tool for you

The market is full of various related products, but not all of them are truly suitable for individual needs. First of all, we should clarify the specific purpose direction and the expected target value range size; secondly, consider the additional services that can be provided within the budget constraints for reference; finally, don't forget to try it out yourself before making a decision! After all, you will not know which one is the most suitable artifact for your team to use until you have experienced it yourself.

Case sharing: benefit analysis after successful implementation

The introduction of this new radar device by a well-known automobile manufacturer has significantly improved the overall efficiency of the production line by about 15%. Originally due to the lack of detailed data guidance, the waiting time caused by the lack of tight connection of some processes was greatly shortened. In addition, due to the reduction of human intervention, the failure rate has also been reduced by more than many percentage points. This is a testament to the fact that the right partners can achieve the established strategic objectives with less effort.

Maintenance and calibration skills: ensure long-term stable operation

if any high-end equipment wants to play a long-term effect, it is inseparable from a scientific and reasonable maintenance plan. Regular cleaning of surface dust to prevent blockage of the induction window is a very basic measure. Timely replacement of aging parts is also one of the essential work contents. Of course, it is also very important to carry out comprehensive functional tests according to the instructions in the instructions to confirm that all performances are still within the normal range. Only in this way can we ensure that we always meet every challenge in the best condition during the duration.