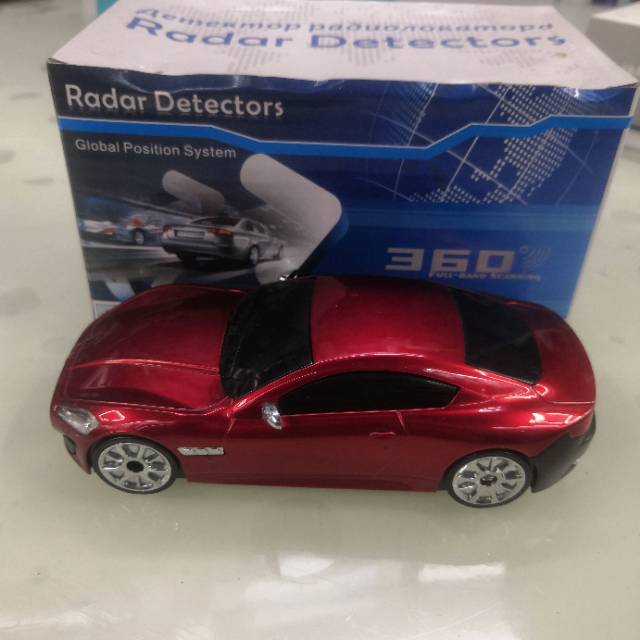

In this era of precision, a reliable rotational speed measurement tool is essential for industrial production and scientific research. Today we will learn more about an advanced solution- high-precision electronic dog fixed flow range speed measurement precision radar . It is highly regarded for its excellent technical characteristics and a wide range of applications.

Secret modern technology: What is the electronic dog fixed flow range speed measurement radar?

This innovative device uses cutting-edge sensor technology and high-frequency signal processing systems to track the speed of rotating mechanical parts in real time. Compared with the traditional contact tachometer, which is easily affected by wear and tear, this non-contact radar device is not only durable but also easy and fast to operate.

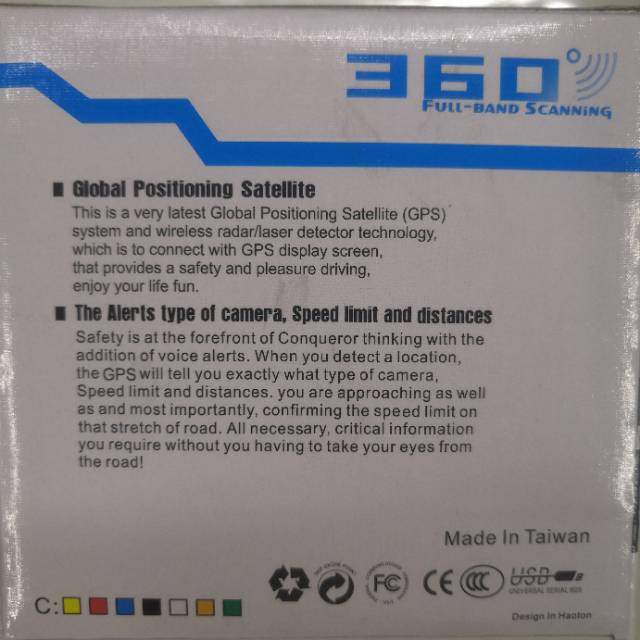

The results calculated by the built-in smart chip are accurate and can maintain stable performance in complex environments.

Core Advantage: Why choose this precision radar for speed monitoring?

First of all, it is worth mentioning that its ultra-high accuracy level, the error value is almost negligible; the second is the strong anti-interference ability, in the noisy or the presence of electromagnetic radiation in the workplace.

It also has an automatic calibration function and a friendly user interface design that enables first-time users to quickly grasp the essentials.

All of these advantages combine to form a complete, high-performance measurement platform for a wide range of demanding mission requirements.

Application scenario analysis: actual case analysis from production line to laboratory

In manufacturing:

For example, the engine test station on the assembly line of an automobile manufacturer needs such high-end instruments for dynamic monitoring to ensure that the product quality pass rate reaches the highest standard while reducing the proportion of rework costs.

In academic research institutions, it is more used to explore the boundaries of unknown areas:

As astronomers observe the laws of distant galaxies, they may rely on such professional-grade hardware to obtain key parameters to deduce the mysteries of the universe.

With flexible functional module combination options and portable compact design concept, it has become one of the universal star products across industries.

Installation and debugging tips: Get started quickly with your high-tech measurement assistant

In order to help customers get started with the device faster, the manufacturer has specially compiled a detailed operation manual covering every detail and step description. It focuses on the following aspects:

-connect the power cable correctly and confirm whether the voltage level matches

-adjust the angle direction of the detector until the best reception strength feedback is obtained

-set the predefined threshold interval to trigger the alarm mechanism instantly to remind the abnormal situation

After following the above guidelines, even novice Xiaobai can easily complete the entire deployment process without worrying about any potential risks.

Maintenance and Upgrade Plan: Ensure Long-Term Stable Performance

regular preventive maintenance is one of the effective ways to prolong the service life. it mainly includes cleaning the accumulation of dust and particles on the surface, checking the firmness of the welding points of the circuit board, verifying the update status of the software version, and so on. it forms part of the overall life cycle management plan.

At the same time, manufacturers will continue to introduce new model iterations to maintain market competitiveness and bring more value-added possibilities to customers.